Looking for more information?

Let us help you on your way.

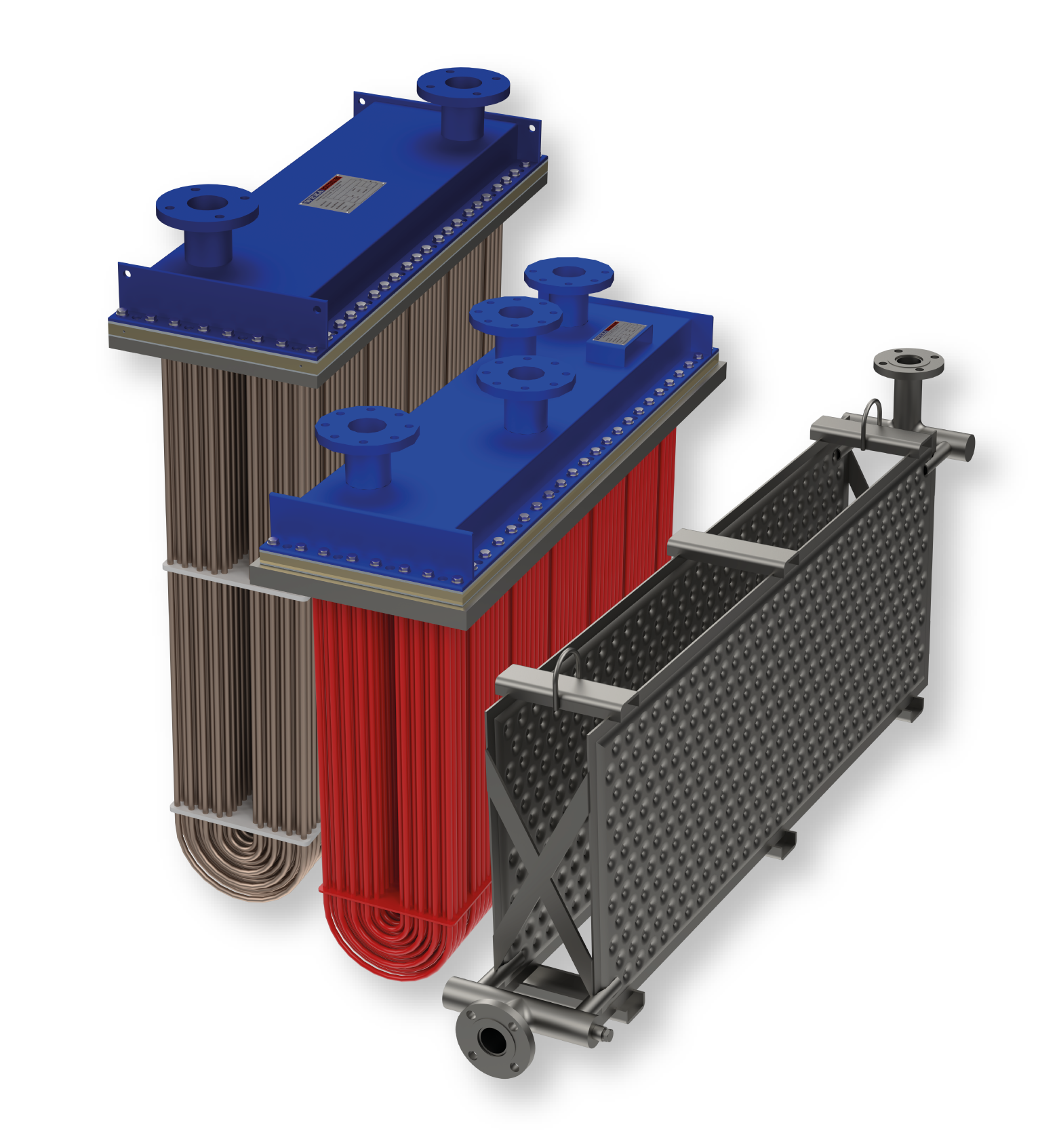

Bundled to perfection

Cooling Solutions

At WEKA Marine, we offer an extensive portfolio of cutting-edge cooling solutions tailored to meet our clients’ diverse needs. Whether you’re seeking efficient cooling for maritime vessels or industrial settings, our solutions deliver exceptional performance, energy efficiency, and reliability.

Stay cool, sail cool

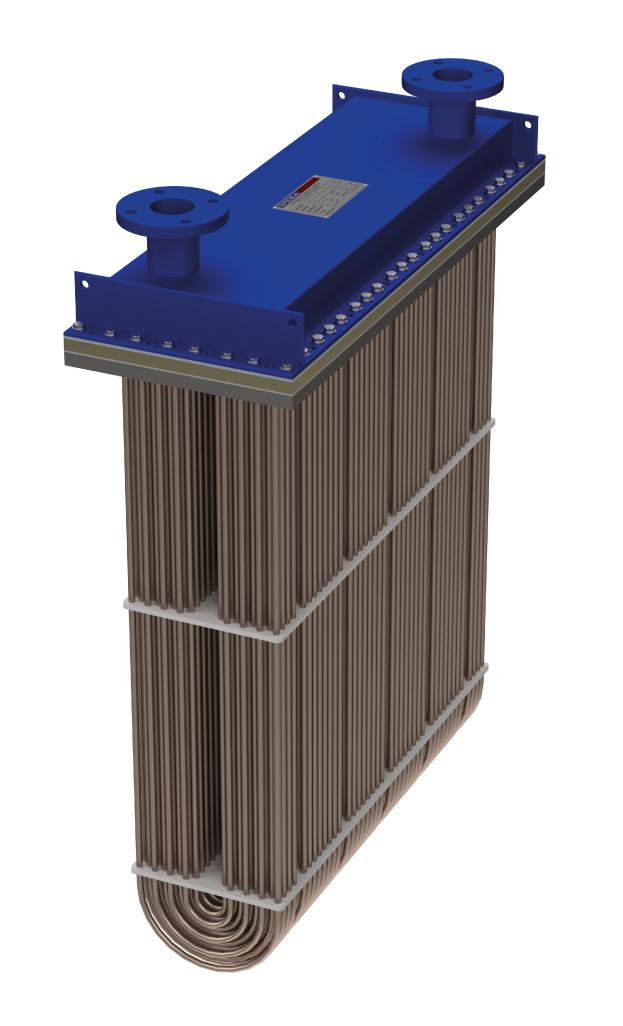

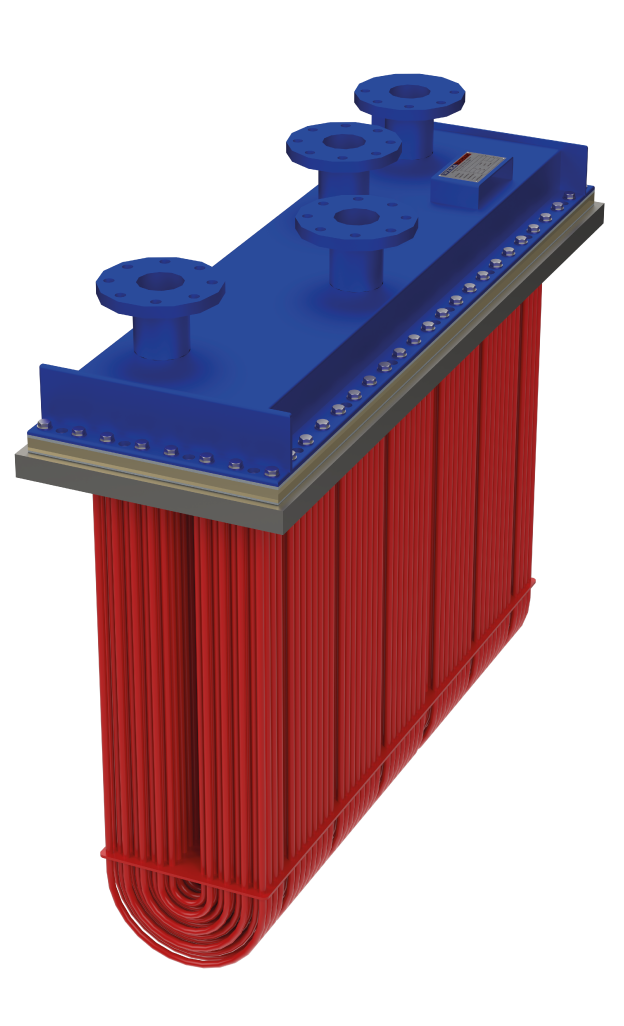

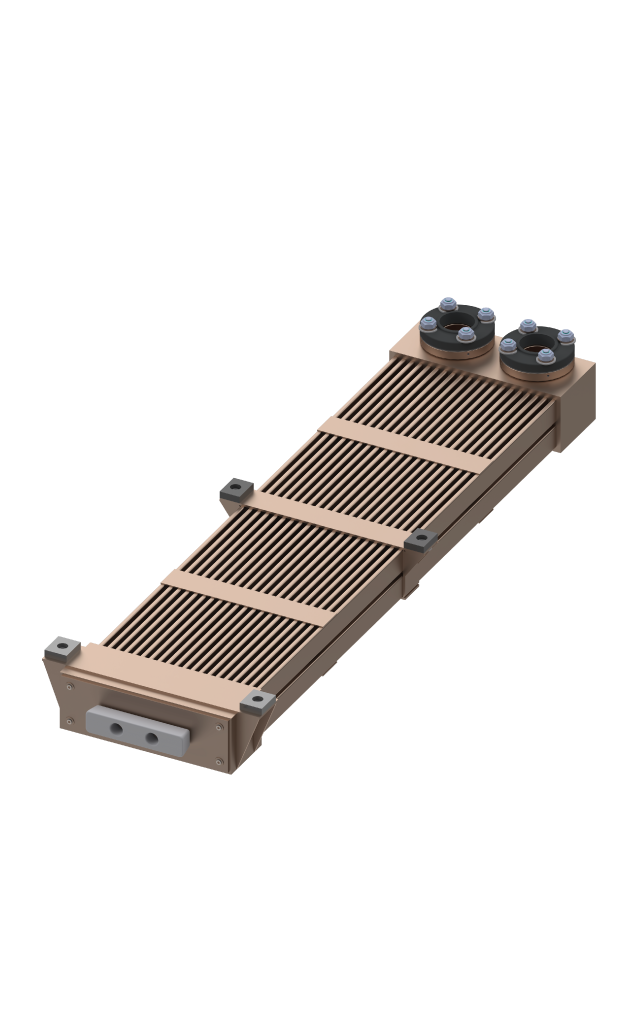

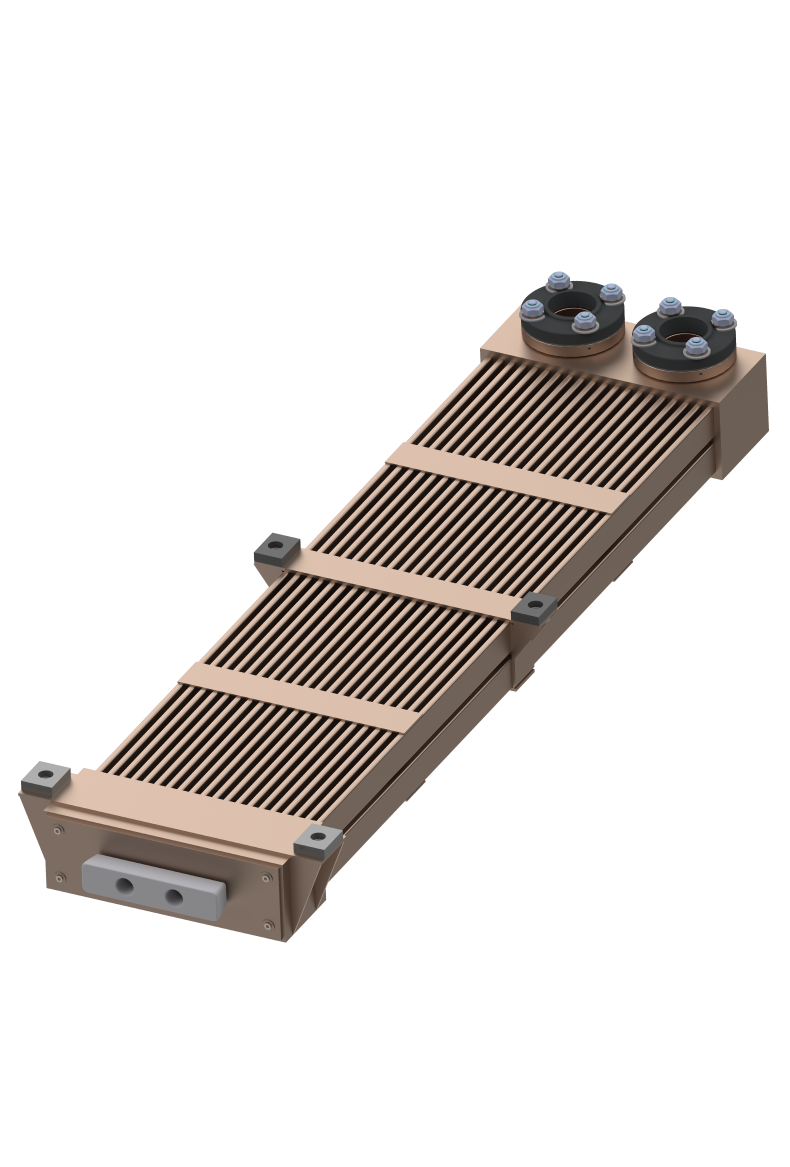

Box coolers

Maintaining optimal operating conditions for marine engines and onboard systems is paramount to ensure the efficiency and performance of vessels. With a wealth of experience spanning decades, Weka Marine specializes in providing rugged heat exchangers capable of withstanding the harsh conditions of the open seas.

Engineered to cool

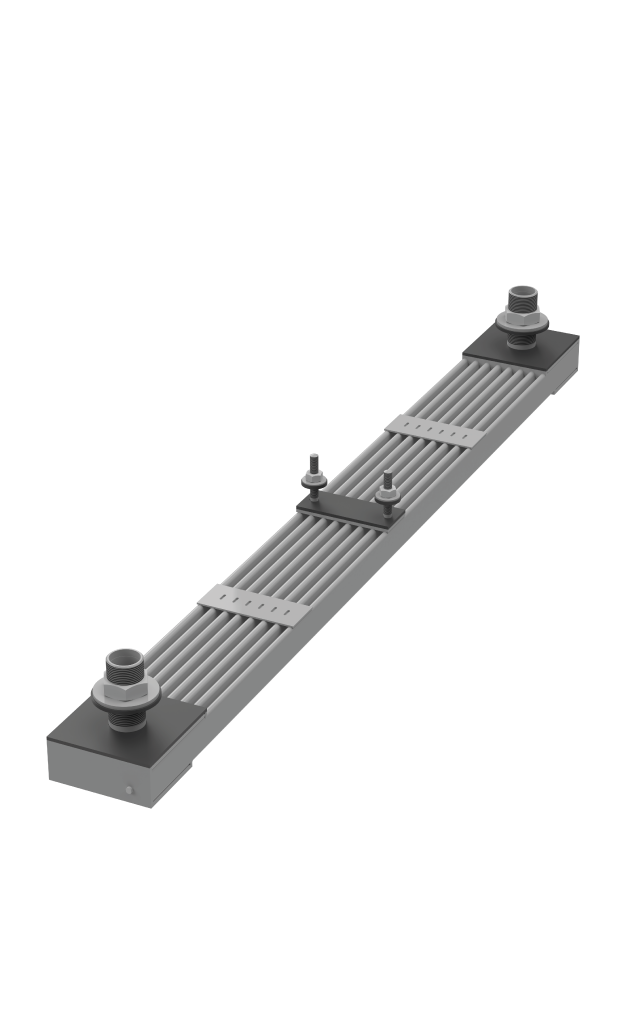

Keel Coolers

A keel cooler is a closed circuit cooling system mounted externally on the vessel’s hull below the waterline. The concept of keel cooling is similar to the application of a radiator on a car. Engine coolant is circulated through the keel cooler, which transfers heat from the coolant before it returns to the engine. The keel cooler is in constant contact with seawater allowing the cooling system to efficiently transfer heat between the coolant and seawater.

Efficient cooling systems

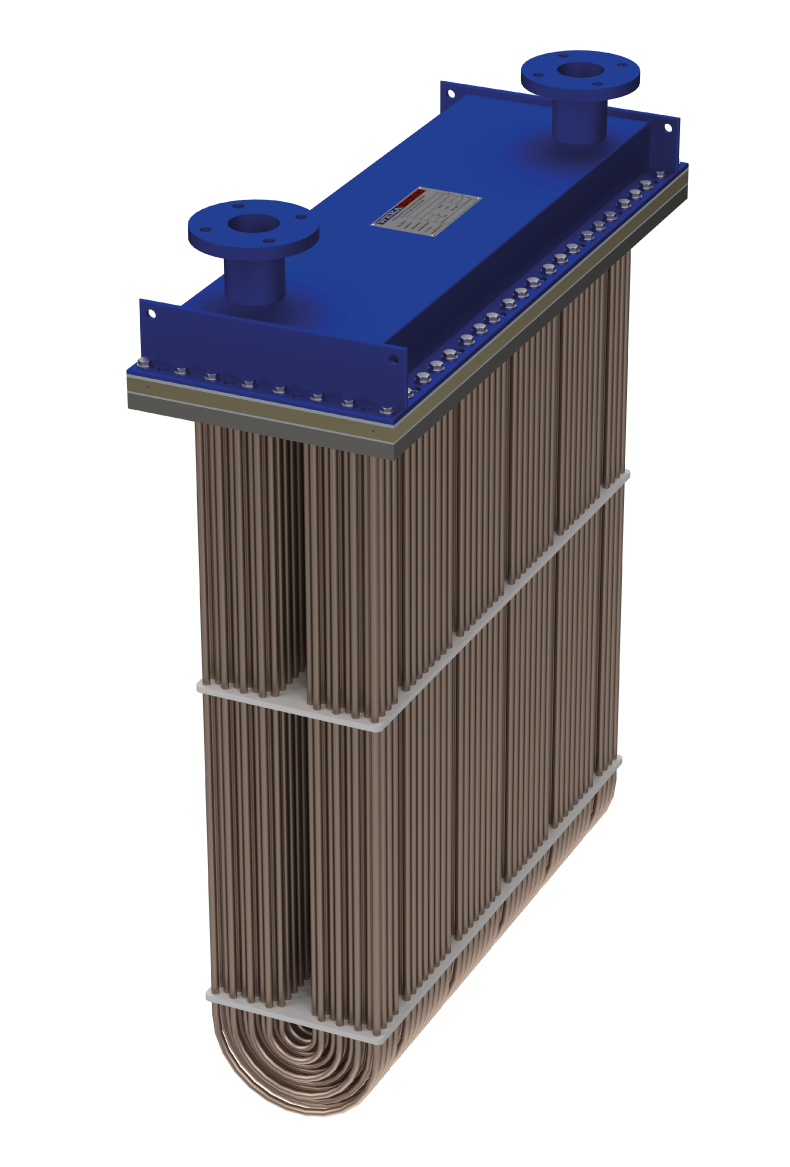

Steel Coolers

Steel coolers are efficient cooling systems designed for installation in several maritime, stationary and industrial applications. Steel coolers cooling the primary circuit using open water. A closed-circuit cooling system, which do not need any water-filters, valves, inboard heat exchanger, raw water pumps, seawater piping and strainers. The Steel coolers can be mounted externally as well as internally into the ship’s hull.

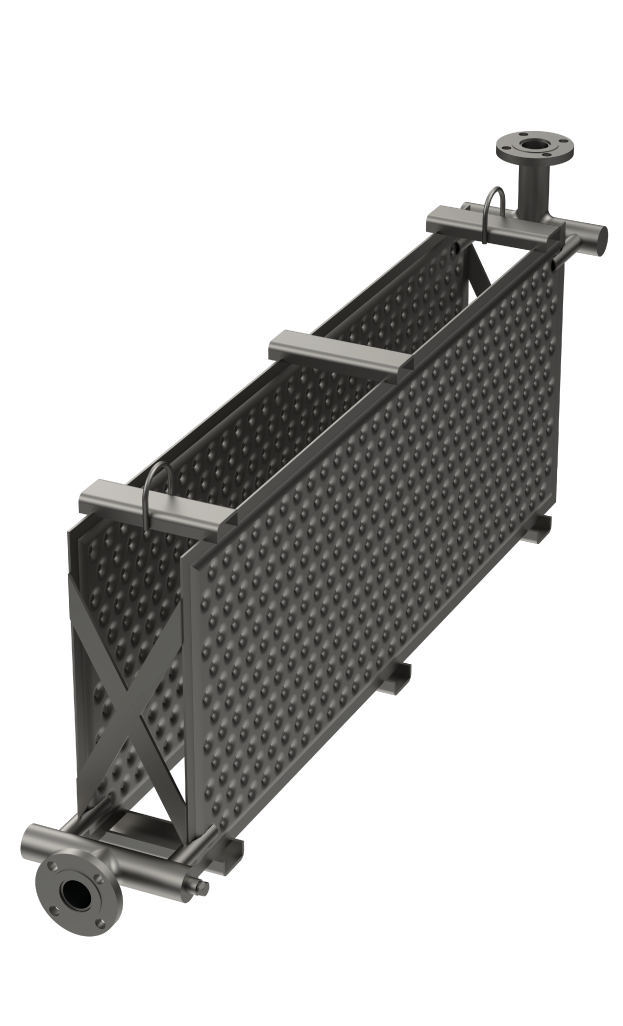

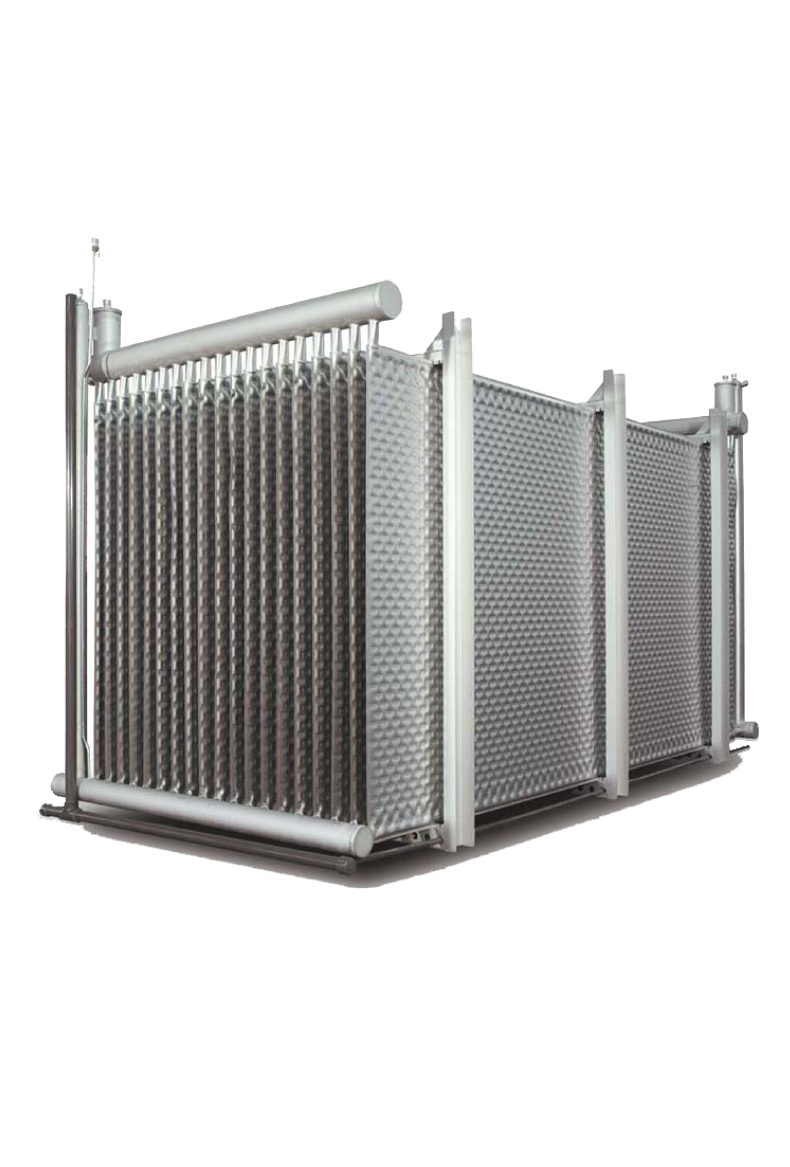

Omega Laser Plate

Laser Plate Heat Exchangers

The Omega Laser Plate is designed to maintain the temperature of fluids (oil, water, asphalts, etc.) in the cargo holds of a vessel and to also heat up fluids prior to reaching a port for ease of pumping-out. The Omega Laser plate consists of two (stainless) steel sheets that are laser welded together by welding a custom circle weld pattern. The outside perimeter of the laser plate is fully laser welded to create a pressure boundary. The laser welding process is a fully autogenous welding process where the Omega laser welding machines melts the materials together, no filler materials are being used this process.

Our experienced field engineers are at your disposal

Services & Feasibility studies

Our cooling solutions are used for cooling marine propulsion engines, generator sets, reduction gears, and auxiliary systems onboard vessels of all sizes worldwide.

Each solution is engineered to meet the requirements of your engine, vessel, and operating conditions. Next to our cooling solutions, Weka also offers a wide range of other marine products.

Bundled to perfection

NEWS