Amazing results after a 6 week feasibility study

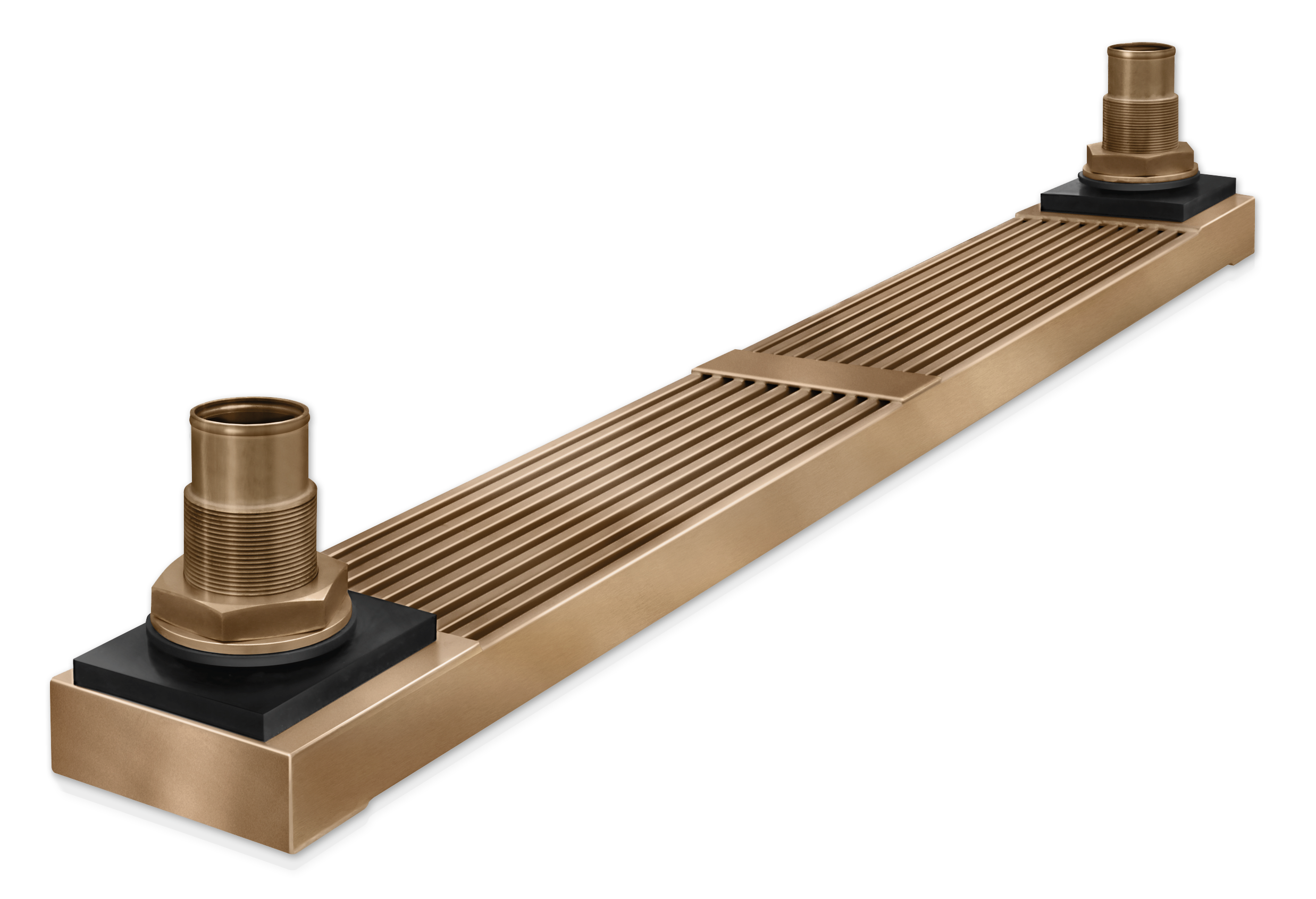

90/10 Copper-Nickel Enhanced Surface

Natural Anti-Fouling

This image illustrates a comparison between traditional aluminum brass tubes with hard baked coating (left side) and uncoated 90/10 copper-nickel tubes (right side). It’s the result of a six weeks feasibility test. The high copper content of the tubing provides natural anti-fouling capabilities, offering protection against marine growth. Copper alloys possess an inherent natural resistance to biofouling. Clearly, the 90/10 Cu-Ni alloy is resisting fouling from algae mussels and other marine growth. For clarification, the biofouling resistance of copper alloys is due to the copper in the protective oxide film; it is not from the leaching of copper ions.

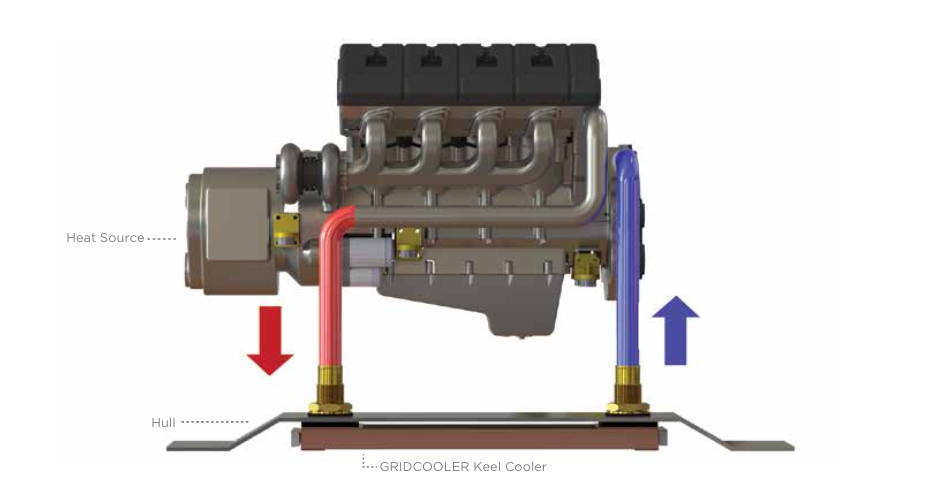

Get more in-depth information about our GRIDCOOLER – Keel cooler

Download our Brochure

Gridcooler Keel Cooler

Send download link to: