Environmentally friendly solution

Box Cooler Protection

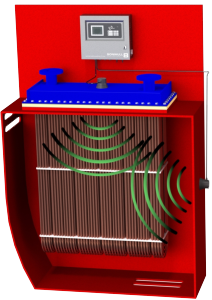

Ultrasonic anti-fouling system

Anti-fouling system for Coated Box Coolers

Our ultrasonic anti-fouling system is designed to keep our Coated Aluminium/Brass clear of algae, barnacles, and mussels to maintain their optimum cooling performance for the vessels critical onboard systems. There are no expensive anodes to replace, no drilling of the box cooler lid, and no specialist installation required compared to impressed current systems. All parts of the ultrasonic system are fitted on the dry side of the box cooler and its sea chest compartment. This avoids the need for any additional surveys and costs for classification documents. Our ultrasonic systems are an environmentally friendly solution, and no toxins or metallic compounds are released into the seawater.

Get more in-depth information about our box coolers

Download our Brochure

Boxcoolers

Send download link to: