Amazing results after a 6 week feasibility study

Copper-Nickel 90/10 Advantages

Natural Anti-Fouling

This image illustrates a comparison between traditional aluminum brass tubes with hard baked coating (left side) and uncoated 90/10 copper-nickel tubes (right side). It’s the result of a six weeks feasibility test. The high copper content of the tubing provides natural anti-fouling capabilities, offering protection against marine growth. Copper alloys possess an inherent natural resistance to biofouling. Clearly, the 90/10 Cu-Ni alloy is resisting fouling from algae mussels and other marine growth. For clarification, the biofouling resistance of copper alloys is due to the copper in the protective oxide film; it is not from the leaching of copper ions.

- Eliminates raw water pumps, strainers, and filters

- Virtually maintenance free

- Cools engines up to 40,000 kw

- In-hull protection

Depending on your operating conditions and hull design

Installation & design options

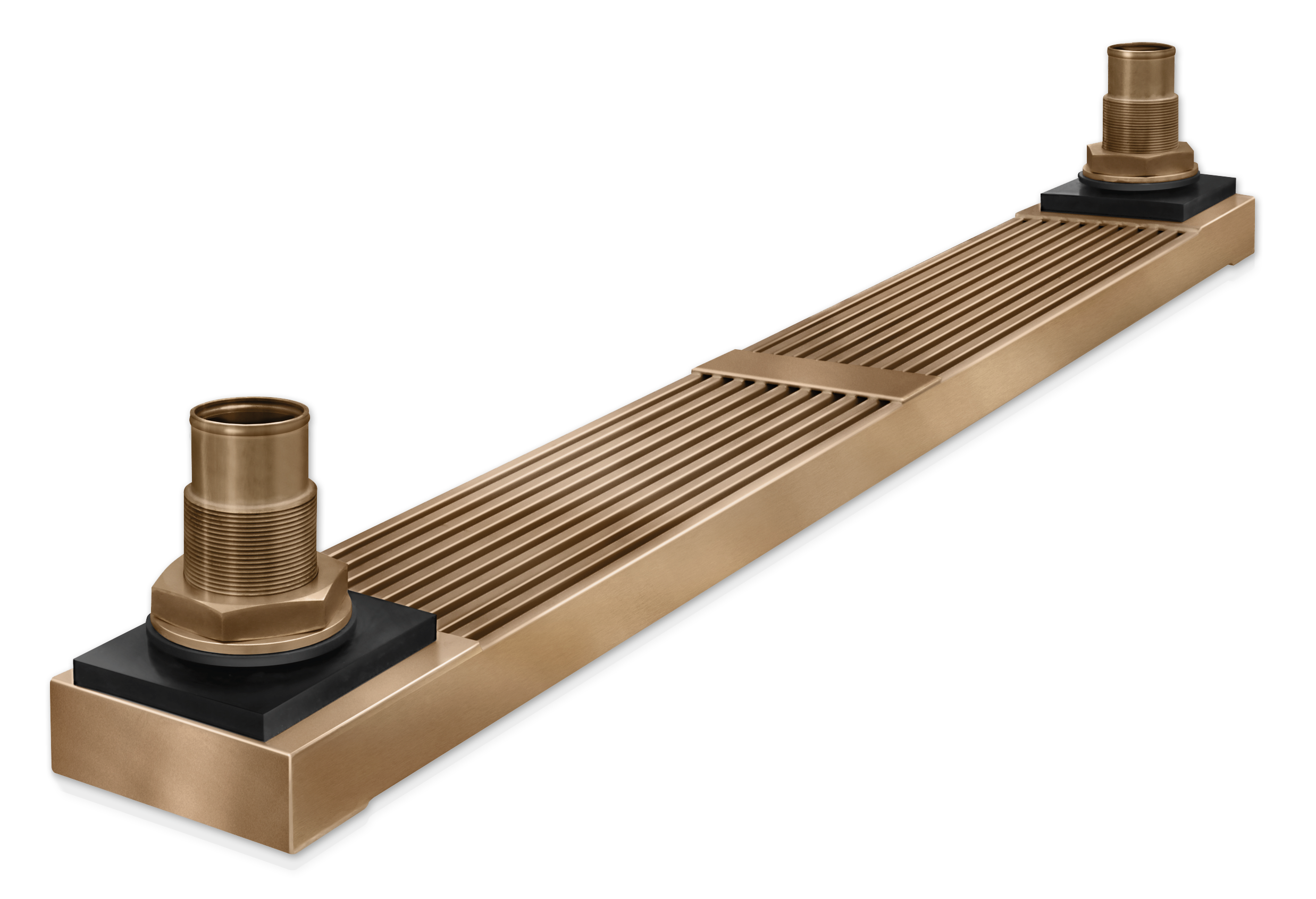

Keel Cooler

Recessed

Recessing a GRIDCOOLER Keel Cooler streamlines the installation and provides significant protection from potential damage. Independent tests conducted at the Vienna Model Test Basin have shown that drag is negligible when the unit is recessed into a ship’s hull. The position of the recess can be located on the side or bottom of the hull. This type of installation is common in new projects and ideal for fast-moving vessels.

External

An external installation typically applies fairing and side plates for added protection and to improve streamlining. This mounting option is commonly used in retrofitting projects.

Side Mounted

Mounting the GRIDCOOLER Keel Cooler on the side of the hull prevents potential damage to the unit. It is ideal for situations where a keel cooler cannot be mounted to the bottom of the hull. Note: When recessing the unit into the side of the hull for generator sets and/or equipment operating at dockside, angle the top of the recess box to allow convection current over the cooler.

Industrial Installation

The GRIDCOOLER® Keel Cooler gives you the choice of being able to mount the units in several configurations. Typically mounted in the suction or discharge sump, the keel coolers can be supported by means of brackets (customer supplied) or the units can be supplied with mounting feet for mounting directly to the sump wall or floor. Flanged connections are available and are supplied with corresponding mating flanges.

Stacked GRIDCOOLER

When faced with limited space or larger cooling requirements, a stacked GRIDCOOLER® Keel Cooler reduces the footprint of the keel cooler while providing greater heat transfer. The design is ideal for cooling larger engines, reducing the number of units required, or fitting into an existing application in the case of repowering.

Angled Tube GRIDCOOLER Keel Cooler

An angled tube GRIDCOOLER Keel Cooler optimizes the heat transfer for side mounted zero knot or stationary applications. The design exploits the natural convection current created by the heat exchanger. The unique position and angle of the tubes are crafted to maximize the flow of raw water between the tubes. This configuration also resists the collection of silt and other debris from building up on the unit.

Aluminium – 5000 Series

An angled tube GRIDCOOLER Keel Cooler optimizes the heat transfer for side mounted zero knot or stationary applications. The design exploits the natural convection current created by the heat exchanger. The unique position and angle of the tubes are crafted to maximize the flow of raw water between the tubes. This configuration also resists the collection of silt and other debris from building up on the unit.

Classification

Upon request the GRIDCOOLER Keelcooler can be supplied with a test certificate of one of the well-known classification societies. For example, ABS, Bureau Veritas, DNV-GL, Lloyds Register of Shipping, RINA, RMRS, RRR and various others upon request.