Engineered to cool

Cooling Solutions

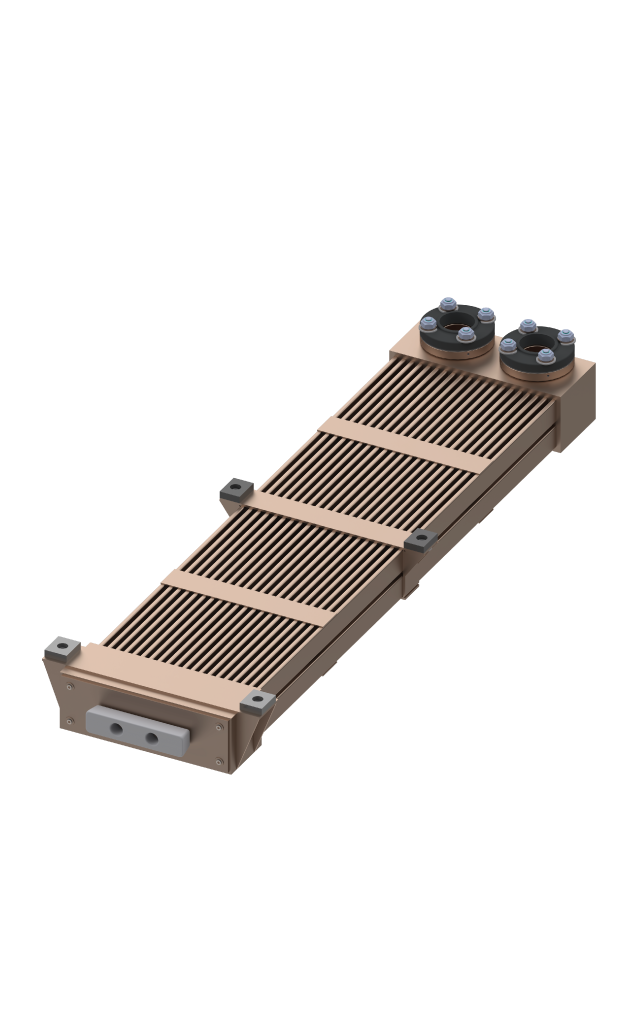

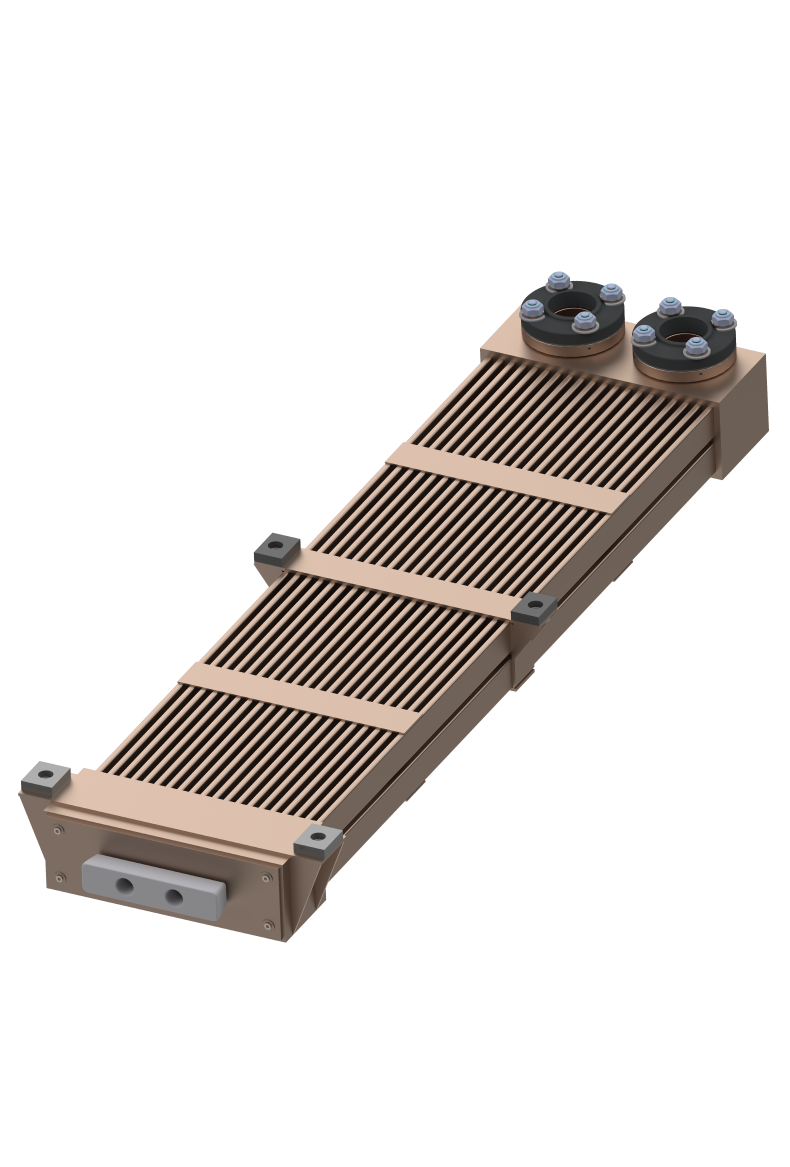

Our commitment to quality means you get a reliable, long-lasting cooling system from the pioneer of the rectangular tube keel cooler. Each marine heat exchanger is engineered to meet the requirements of your engine, vessel, and operating conditions. The GRIDCOOLER Keel Cooler has continually evolved to meet the requirements of naval architects and the marine industry worldwide.

One-piece Header Design

Keel Coolers

A keel cooler is a closed circuit cooling system mounted externally on the vessel’s hull below the waterline. The concept of keel cooling is similar to the application of a radiator on a car. Engine coolant is circulated through the keel cooler, which transfers heat from the coolant before it returns to the engine. The keel cooler is in constant contact with seawater allowing the cooling system to efficiently transfer heat between the coolant and seawater.

Get more in-depth information about our GRIDCOOLER – Keel Cooler

Download our Brochure

Gridcooler Keel Cooler

Send download link to: