Maintain the temperature of fluids

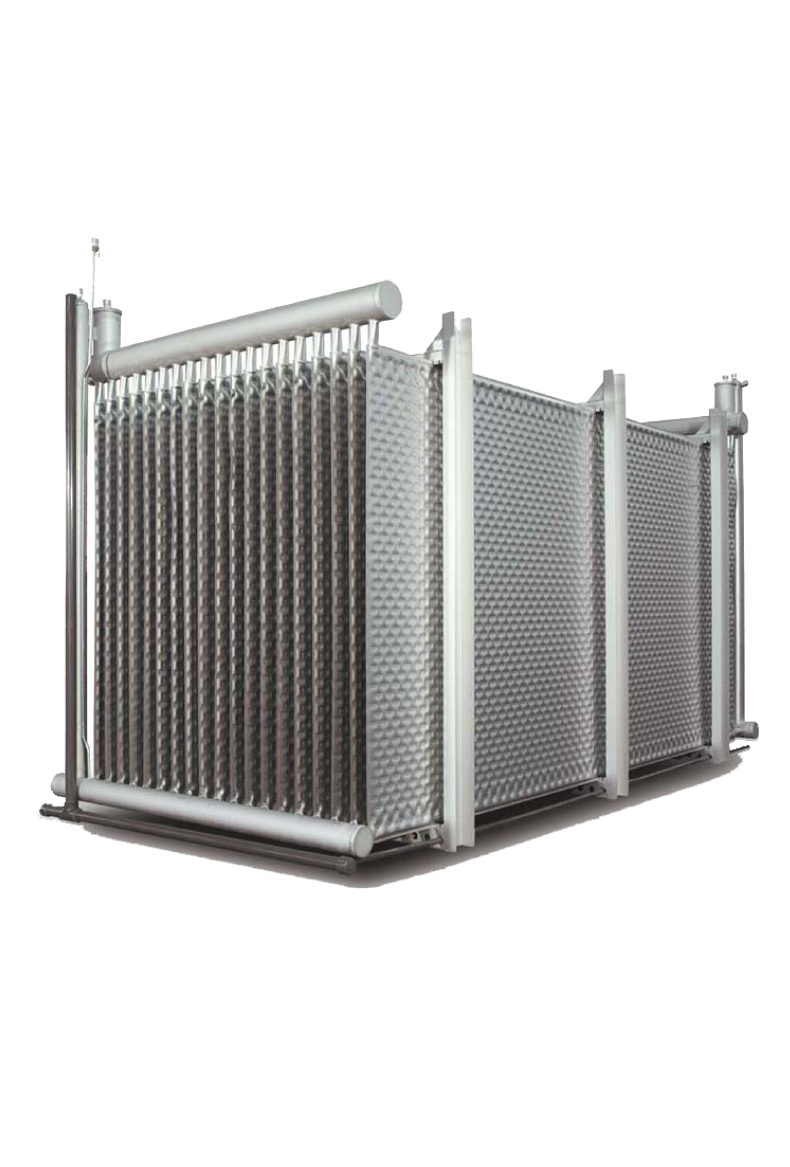

Laser Plate Heat Exchanger

The Omega Laser Plate is designed to maintain the temperature of fluids (oil, water, asphalts, etc.) in the cargo holds of a vessel and to also heat up fluids prior to reaching a port for ease of pumping-out. The Omega Laser plate consists of two (stainless) steel sheets that are laser welded together by welding a custom circle weld pattern. The outside perimeter of the laser plate is fully laser welded to create a pressure boundary. The laser welding process is a fully autogenous welding process where the Omega laser welding machines melts the materials together, no filler materials are being used this process.

The Laser Plate is hydraulically inflated by using water through a hydrostatic pump. Hydraulically inflating will guarantee for a safe inflation process. Other inflation processes can be used depending on the application. The inflation process pressurizes the two sheets which allows the material to deform, a cavity will be created for use of a heat transfer medium. The Omega laser Plate can be used with either liquids, steam or refrigerants.

Plate implementations are endless

Applications

The potential applications for Laser (pillow) Plate implementations are endless. Below you will find an overview of some of the applications specially designed for the maritiem industry. Please let us know if you have an application that is not indicated below and we will gladly look into this.

Ensuring they meet the exacting demands

Marine Applications

- Ballast tank freeze protection

- Cooling and heating of liquid cargo tanks

- Cooling and heating of oil tanks

- Refrigerated cargo holds on board of fishing vessels

- Diesel fuel preheaters

- Exhaust gas coolers

- Cooling and heating of conveyors

- Cooling and heating of all required flat heat transfer surfaces

- Super structure & gangway heaters/De-iceing

- De-iceing of helicopter platforms

- Immersion plates Plate banks

- Falling Film Chillers Immersion Chillers Ice banks

- Ice machines

- Clamp-on plates

- Cooling and heating plates

- Heat recovery banks

- Custom assemblies

- Installation cost significantly lower

- Reduced installation time

- Lower weight and more cargo capacity

- Superior heat transfer coefficient (50%+ over pipe).

- Reduced energy consumption due to higher efficiency

- Reduced thermal oil volume (reduces weight of oil on board, lower initial fill cost, lower disposal cost).

- Even distribution of cooling and/or heating media. Design not limited due to complex geometries.

- Not susceptible to flow induced vibrations, vibration fatique cracking, and water hammer from condensate blocking)

- Easier to clean cargo holds

- Banks are easy to clean and service

- Eliminates damage to cargo hold coating

- Supply and return manifolds can be routed through the center of the ship

- Improved control characteristics.

- Austenitic materials (304, 304L, 316, 316L, 316Ti, 317, 321)

- (Super) duplex materials (2205, 2507, 2304, LDX-2101)

- High nickel alloys (Nickel, Hastelloy, Alloy, Inconel)

- Titanium 254-SMO 904L

- 22ga on 14ga

- 22ga, 20ga on 12ga

- 22ga, 20ga, 18ga on 10ga

- 20ga, 18ga, 16ga on 7ga/ 3/16”

- 18ga, 16ga, 14ga on 1/4″

- 18ga, 16ga, 14ga on 5/16″

- 16ga, 14ga on 3/8″

- 16ga, 14ga on 1/2″

- 22ga

- 20ga

- 18ga

- 16ga

- 14ga

- 12ga

- 11ga

- 10ga

We’re on a mission

Maximize your cooling capacity

and support marine life!